.jpg?width=4088&name=Vest2013-CoveredPorch%20(47).jpg) Capped Composite

Capped Composite

As we discussed in an earlier blog post, The Benefits and Drawbacks of Natural Wood Decking Materials, the choices of materials to use on your new deck are constantly expanding. When you’re deciding which way to go, consider the cost, beauty, durability, and availability of the materials. The spectrum of materials, arranged by price, runs from the least expensive treated softwoods, through more costly natural and manmade materials, up to exotic hardwoods and the highest-end synthetic materials that do the best job of mimicking the appearance of wood. In this post, we will look at manmade decking.

Back in 1996, a company named Trex came out with a product made of wood fiber and plastic that quickly won acclaim as an alternative to wood for decks. As a manufactured product, it had a uniform appearance without the knotholes and other drawbacks of lower-quality wood. It was more expensive than the most commonly used wood deck materials, but its long life and relatively low maintenance requirements were expected to outweigh the higher cost. But, those early composite materials were prone to mildew and mold, and some broke down in the sun so, at Kaufman Construction, we shied away from them for years.

In the past 10 years, though, manmade decking products have improved immensely, and we have been installing decks of these materials with great success. The synthetic deck materials can be divided into three general classes:

Composite

Composite

Composites

True composites still are made with a combination of reclaimed wood fiber and recycled plastics. The mold issues have been resolved, and many, many homeowners are enjoying their decks made of this material. These composites are molded with a wood grain and in a variety of woody and earth tones, although those at the lower end of the price range don’t look as wood-like as the more expensive lines do. These decks really do have lower maintenance needs – an occasional good scrubbing usually does the trick – and the material won’t rot or be chewed by insects. An added benefit for the environmentally conscious is these products’ use of recycled wood and plastic.

On the downside, composite planks can cost twice as much as treated wood, the material is notoriously hot on bare feet, it has been known to fade, and scratches or burns of the planks can’t be repaired.

Composite

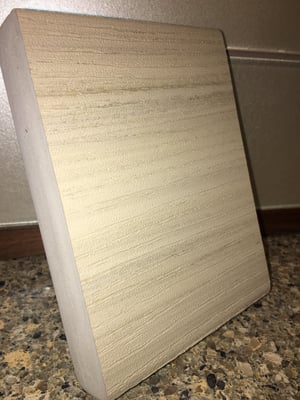

Capped composites

Midway up the manmade continuum are capped composites. These products feature a core of wood-and-plastic composite material with a layer of PVC plastic fused around the outside. The PVC layer contains pigments, ultraviolet light inhibitors, antioxidants, and mold killers. The result is a more expensive, but more durable, deck that resists fading in the sun and infestation by unwelcome microorganisms. In the better products, the pigments are applied in such a way to mimic the natural grain of wood. Over the years, the reduced maintenance replacement costs for these decks can balance out the initial higher price.

Capped Composite

PVC

Decks made entirely of PVC or polymers are the most expensive. They also feature a capped system of PVC over a polymer core. These products feature the same benefits of capped composite materials but are even better at reproducing the look of wood. Their manufacturers offer decades-long warranties against fading and staining and say the highest-end products dissipate heat better than regular composites. As Kaufman Construction builds mostly covered decks and outdoor spaces now, the problems caused by direct sun aren’t much of an issue anymore. These products, as well as the lower-cost manmade materials, are attached using hidden fasteners. This means your deck won’t have screw holes on the surface of the planks, but this system does increase the cost to build a deck.

Plastic decking materials are susceptible to expansion and contraction with changing temperatures, so we’ve learned to design a deck to avoid or hide gaps between the ends of the planks. Also, if the framing under a deck isn’t perfectly level, these materials can appear wavy. Builders typically use green treated lumber for the framing, although metal framing systems are becoming more common and will come down in price.

PVC

.jpg?width=600&name=Cox2010-Exterior%20(6).jpg)

.jpg?width=410&name=Littlefield2013-Porch%20(37).jpg)

.jpg?width=300&name=McKinney%20-%20After%20(35).jpg)